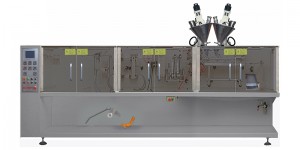

BHS-210D/240D Horizontal Duplex Flat Pouch Packing Machine

contact usTechnical Parameter

| Model | Pouch Width | Pouch Length | Filling Capacity | Packaging Capacity | Function | Weight | Power | Air Consumption | Machine |

| BHS-210D | 60-105mm | 90-225mm | 150ml | 80-100ppm | 3 side seal,4 side seal | 1250kg | 4.5 kw | 200 NL/min | 4300 x970 x1500mm |

| BHS-240D | 70-120mm | 100-225mm | 180ml | 80-100ppm | 3 side seal,4 side seal | 1250kg | 4.5 kw | 200 NL/min | 4500 x 970 x 1500mm |

Packing Process

- 1Film Unwinding Device

- 2Bag Forming Device

- 3Film Guide

- 4Photocell

- 5Bottom Sealing

- 6Vertical Sealing

- 7Tear Notch

- 8Servo Pulling System(optional)

- 9Pouch Cutting

- 10Pouch Opening

- 11Air Flushing Device

- 12Filling Device

- 13Top Sealing

- 14Outlet

Product Advantage

Independent Sealing Device

Independent pouch making, no product no seal

Higher seal strength, less leakage

Better pouch appearance

Light Walking Beam

Higher running speed

Longer operational life span

Dual Filling Station

Reduce filling time by half

Improved filling accuracy

Product Application

BHS-210D/240D Series designed for middle& small size bags, dual filling station and twin-link function, excellent for high speed packing requirement.

- ◉Powder

- ◉Granule

- ◉Viscosity

- ◉Solid

- ◉Liquid

- ◉Tablet

Write your message here and send it to us