8 FQA about Stick Packaging Machines:

1. The customer wants to install a laser coder. Can products be discharged if they are not coded? If so, how?

A: You can add a visual inspection system to the auto vertical stick packing machine. The equipment will have two outputs: one for qualified products and one for unqualified products.

2. Is there any way to detect a poor seal? If pressure testing is used, how is it performed? After the test, how is the seal pressure adjusted to ensure seal integrity?

A: There is no method to detect this problem on the machine yet. Only in the finished product stage will there be pressure testing of the finished product to test the sealing performance.

If it is unqualified, it will be tested and solved based on the product performance, whether the material is powdery or sticky, the sealing strength, the sealing block temperature and other aspects.

3. How does the stick pack machine ensure the film roll is correctly positioned? If the film is slipping, how does the machine's alarm system work?

A: Boevan's VFFS machines all have automatic web correction devices. A magnetic powder clutch controls the film tension to achieve automatic web correction.

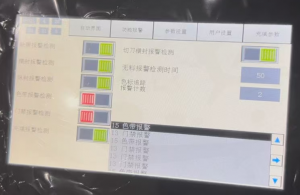

4. What sensors are designed into the vertival stick bag packing machine, and what related alarms can the sensors detect?

A:

- Color mark sensor, used to determine bag length;

- Position sensor, used to determine the origin of the horizontal seal film pull and film placement rack;

- Material level sensor, used to detect material level;

- Temperature sensor, used to control the temperature of the horizontal and vertical seals;

- Web guide sensor, used to control the left and right deviation of the film;

- Low film sensor, which, upon detecting low film, will first generate an alarm and then shut down the machine after 5 minutes;

5. Is there any detection method to detect defects in finished bags? The customer requires defective bags to be removed during the final packaging stage. How are these removed based on the specific situation?

A: Manual inspection;

6. What is the production capacity of the 4-lanes stick bag packaging machine?

A: 4-lane stick packing machine packing capacity up to 200 ppm(1800 bag/h); multilane stick bag packing machine Max can be 600 ppm(30,000bag/h)

7. Can the bag not be sealed if no material is filled? How does the vffs machine detect when no material is filled?

Answer: The buffer tank will have a low-material alarm, and the machine will shut down if there is no material. The multilane stick pack machine can be equipped with a re-inspection system for each row, and bags that are not filled or have weight deviations will be rejected.

8. How long does it typically take to change over a multilane vffs machine? Which parts need to be replaced?

A: If changing products, CIP cleaning takes approximately 2 hours, and equipment adjustment takes approximately 30 minutes. If the bag shape and width remain unchanged, changing products only requires replacing the film roll.

What other technical information would you like to know about the automatic stick bag packing machine? Contact me:

Monnie

Email: info@boevan.cn

Address: +86 18402132146

Address: No. 1688, Jinxuan Road, Nanqiao Town, Fengxian District, Shanghai, China

Post time: Aug-12-2025